Machines and Solutions > Tube filling machines > Linear tube filling machines > MTL-200/2 Linear Tube Filling Machine

MTL-200/2 Linear Tube Filling Machine

Rotary Tube Filling Machines

Linear Tube Filling Machines

High-Capacity Tubes Feeders

Intermittent Motion Cartoners

Continuous Motion Cartoners

Tablets Deduster Machines

MTL-200/2 Linear Tube Filling Machine: specifications

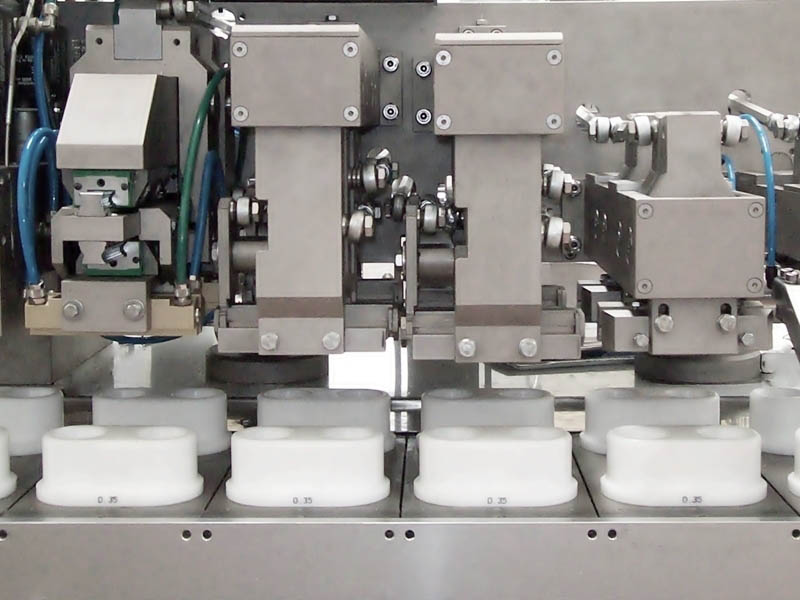

MTL-200/2 is a fully automatic, ultra high-performance linear tube filling machine.

Characterized by a high standard of quality, it guarantees complete, long-term reliability. Tubes are transported across two rows, with single filling and sealing stations on each row.

- Stainless steel frame

- In-line tube transport

- Four plunging nozzles for feeding from the bottom

- Maximum mechanical rate of 24,000 units/hour

- Tube diameters from 10 to 60 mm

- Tube lengths from 50 to 250 mm

- Horizontal loading and unloading of tubes

- Mechanical head with aluminium pincers (simple fold, double or saddle)

- Hot Air Head for Polyethylene, Laminate, Polyfoil, Coex

- “All in One” single head for plastic materials and aluminium (without format change)

- Easy format change

- Various options and customisation

- Option of shaped tube welding (euroslot, wave, crescent, etc.)

- Option of inserting laser markers in the machine.

- Siemens electronics

- Stainless steel frame

- In-line tube transport

- Four plunging nozzles for feeding from the bottom

- Maximum mechanical rate of 24,000 units/hour

- Tube diameters from 10 to 50 mm

- Tube lengths from 50 to 250 mm

- Horizontal loading and unloading of tubes

- Mechanical head with aluminium pincers (simple fold, double or saddle)

- Hot Air Head for Polyethylene, Laminate, Polyfoil, Coex

- “All in One” single head for plastic and aluminium (without format change)

- Easy format change

- Various options and customisation

- Option of shaped tube welding (euroslot, wave, crescent, etc.)

- Option of inserting laser markers in the machine

- Siemens electronics

Fill in the form to download the machine’s technical data